Building a Basic Simulation

You build your simulation in Simul8 simply by drawing it on the screen.

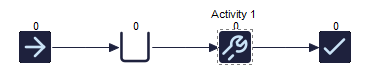

Click the Start Point icon on the toolbar and drop the object somewhere on the screen.

Next click the Queue icon and do the same.

Then place an Activity on the screen using the Activity toolbar icon button (we will copy it in a moment to make a second one).

And finally create somewhere where work leaves the system with the End Point object.

Simul8 has automatically linked them together for you as can be seen by the gray arrows. It does this for simple simulations only. Normally you put the links in, or take them out, by dragging the mouse - see a little later.

You can run the simulation now if you like.

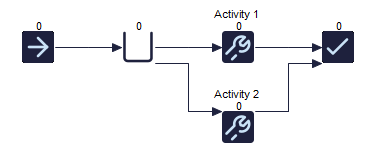

However if you want to put a second Activity in press and hold the “CTRL” on the keyboard and then drag “Activity 1” to a new location on the screen with the mouse. Simul8 has copied the links from the Queue to the Activity, and from the Activity to the End Point.

Now click the RUN button to run the simulation.

Now click the RUN button to run the simulation.

You will see “work” (red balls) moving between each simulation object you have created.

To stop the simulation click the RUN button again - it will stop automatically at the end of a week.

Video

Watch this video series to learn more about building a basic simulation.