Intuitive simulation software packed with powerful features

Make confident, impactful decisions with the world's fastest, most intuitive and effective simulation platform for desktop and the web.

So fast you’ll use it every day

Make decisions in minutes, not months, with an intuitive interface and powerful features designed to help you build simulations at blisteringly fast speed.

Drag and drop simulations

Model any business process using a drag-and-drop interface that’s completely focused around speed to build and run simulations.

Intelligent building blocks

Use powerful building blocks to simulate and experiment with any element of your business, no coding needed.

Reusable components

Empower faster, routine decisions by saving and adding your most frequently used workflows, equipment and resources into any simulation.

One click simulations

Create instant simulations with Process Mining, BPMN, Microsoft Visio and many other import features.

Build, run and share simulations anywhere

Simul8 anytime, anywhere, with anyone. In today’s remote working world, effortless access to the productivity tools you rely on every day has never been more important.

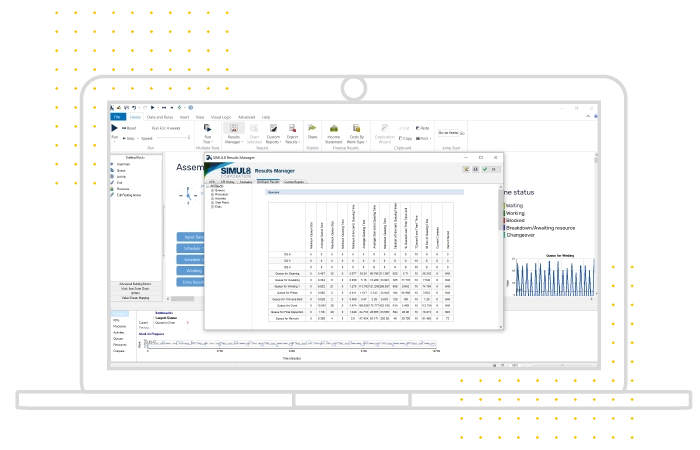

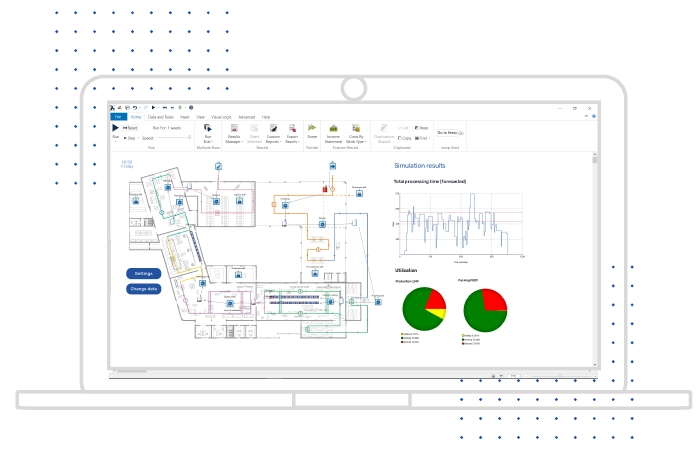

Fuel decisions with fast, focussed results

A lightning-fast results engine helps you to uncover the opportunities and outcomes that will fuel better, confident day-to-day and strategic decisions.

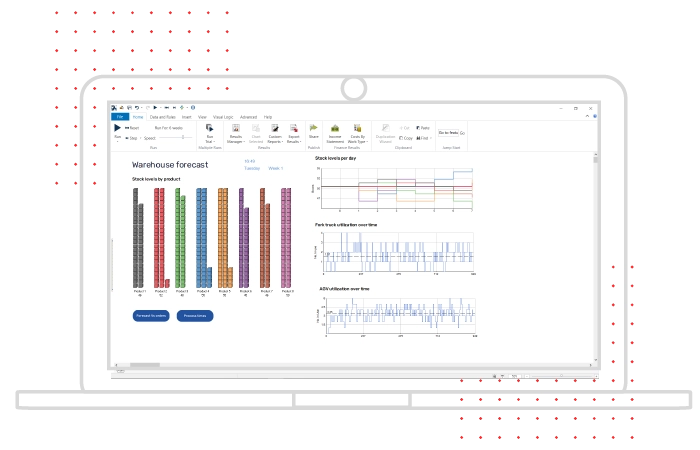

Base decisions on truth with data integrations

You don’t need data to start testing your ideas and unlocking game-changing insights, but it’s easy to integrate your data sources into simulations.

Rapid data connections

Link simulations to everyday productivity tools like Excel, Google Sheets, text and CSV files, or dynamic database connections via SQL and ODBC.

Instant process mined models

Import transactional logs from ERP, workflow management and other information systems to build an instant simulation of any process.

Connect to live data sources

Sync simulations with live data to build digital twins of your process or system for day-to-day, operational decisions.

Experiment using distributions

Use Simul8’s pre-built distributions for quick experimentation or create your own to match your business’ arrivals or schedules.

Visual and interactive insights

Visualize your process with engaging, animated simulations that bring your ideas to life and win stakeholder buy-in in a fraction of the time of complex 3D models.

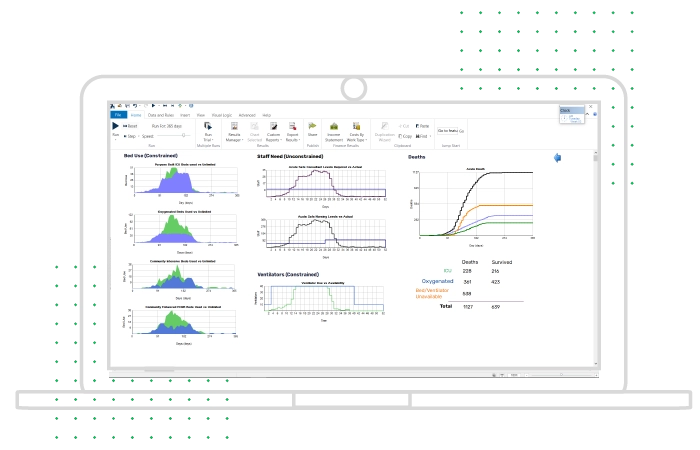

Multi-method modeling to Simul8 any decision

Experiment with and test the outcome of any type of decision cost-effectively - without risk - using Simul8’s powerful multi-method simulation modeling.

Discrete Event

Model any existing or proposed business process as a sequence of steps, like drawing a flow chart.

Agent-based

Model the behaviour of individual people or machines to understand their impact on a process.

Continuous

Model objects that have a continuous motion, like the flow of water or gas in tanks and pipes.

Hybrid

Combine different techniques in one simulation to model a limitless range of processes.

Limitless customization

Simul8’s APIs and powerful scripting tool, Visual Logic, allow for even deeper customization when you need it.

Next generation simulation engine

We’ve been building simulation software for over 30 years. We changed the simulation market with the most accessible simulation tool, and we’ve never stopped innovating since! Our next gen simulation engine takes advantage of the latest innovations to bring you real time adaptive simulations.

APIs and Data Hooks

Use our APIs and live data hooks to link us into your technology stack and systems.

Process Mining

Build the entire structure of your simulation from your data log. One click and its done!

Machine Learning

Build the rules and timing of your simulation from your data log. Your simulation is always up to date with no lengthy validation periods.

Share

Give anyone in your org the power of simulation without needing to know how to build. They can run Simul8 for daily decision making.

Boost your simulation capabilities

OptQuest

OptQuest seamlessly integrates with Simul8, transforming your simulations from “what if” to what's best. With intelligent optimization, you can test thousands of parameter combinations in minutes—uncovering the most efficient, cost-effective, and impactful solutions with confidence.

Version Control

Keep track of every change with ease. Version Control allows you to manage multiple iterations of your simulations, collaborate efficiently, and ensure consistency across your projects.