SIMUL8 ensures feasibility of $31 million OR expansion project

Memorial Health System (MHS) is adding capacity to its operating rooms to cope with a 5% annual increase in demand for surgeries. With a $31 million price tag, the Operations Improvement team at MHS needed to be sure that the expansion would meet their needs. Testing the architect�s plans in SIMUL8, it was determined that the new design would not be adequate for patient flow.

Various new proposals were then tested in SIMUL8, including the addition of a 3rd elevator, and agreement reached on new designs for the development. Following the success of the project further Lean Six Sigma projects have been chartered to streamline scheduling processes and OR turnover process to further reduce variation and increase capacity.

Memorial Health System

Memorial Health System

One of the leading healthcare organizations in Illinois, Memorial Health System of Springfield is a community-based, not-for-profit corporation dedicated to patient care, education and research.

With nearly 5,900 staff members, partnering physicians and hundreds of volunteers, they are dedicated to improving the health of the communities they have served since 1897. In 2010 alone, MHS's three hospitals in Springfield, Lincoln and Taylorville provided care to more than 27,900 inpatients, more than 612,000 outpatients and more than 96,000 patients in their three Emergency Departments. Their highly skilled team has a passion for excellence and is dedicated to providing a great patient experience for every patient every time.

So, when faced with the architectural design proposal for a $31 million operating room expansion project, the Operations Improvement team at MHS turned to simulation to test feasibility of the proposals and to ensure that any development would continue to deliver on patient experience.

Capacity Planning in Healthcare

Faced with a 3% to 5% annual increase in the number of surgeries in recent years, part of the project will see two floors of surgical space added at the medical centre. The $31 million expansion project will add five operating rooms, bringing the total to 22 ORs, and representing a 29% increase in capacity.

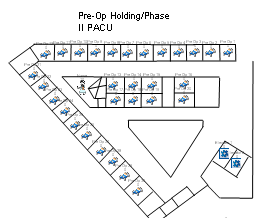

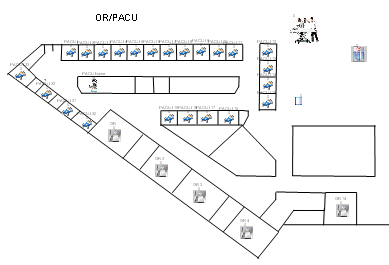

To test the feasibility of the proposals Todd Roberts, System Director of Operations Improvement at MHS, used SIMUL8 software to simulate flow for all aspects of the operating room expansion project including; pre-op admission, transport to the OR, OR time, and post-anaesthesia care units (PACU) for admitted and outpatient surgery.

The simulation allowed Todd to test assumptions for capacity based on expansion of the 5 operating rooms (and pre-op/PACU beds) and increased volumes of 15% over the next 5 years.

Identifying bottlenecks and scenario testing

With rooms split over two levels, the proposals included two elevators to transport patients between floors. Using the simulation Todd could visually identify all process bottlenecks and determined that, with a surge of patients transported to the OR for first and second-case starts, that two elevators from the pre-op holding area to the ORs would not be adequate for flow.

It was concluded that this bottleneck would lead to staff, physician, and patient dissatisfaction. So, a variety of scenarios were experimented with to remove the bottleneck with the optimum solution being the introduction of a third elevator shaft.

The simulation also highlighted that the issue increased overall variation by 30 minutes per case throughout the day. The discovery of a downstream increase in variation could not have been achieved and recognized using static waiting line models. Unlike static models, like Excel, simulation can capture the unpredictable variations and randomness of real life like; patients arriving late or physicians being unavailable. The ability to model this variation, therefore, allows us to better understand how a system will function under a variety of scenarios and avoid misleading results.Getting management buy-in and projecting future needs

Once findings were presented to management the decision was made to add the third elevator to satisfy flow demand ensuring staff and patient satisfaction. The visual and interactive nature of the simulation allowed management to see first-hand the bottlenecks at the elevators and provided a compelling case to assist the proposal of a third elevator.

Subsequent studies conducted for a projected increase in volume year over year have confirmed that the proposed building will provide adequate facilities for the next 20 years.

Following the success of the project further Lean Six Sigma projects have been chartered to streamline scheduling processes and OR turnover process to further reduce variation and increase capacity.

More